You see it everywhere—that pink panther running over the pink fiberglass insulation that looks like it’s falling out of the walls or off of the basement ceiling above you. Fiberglass insulation uses its color and mascot to pull you in, leading you to believe that it is the most effective in saving energy in your home.

But before you jump into the familiarity of fiberglass, let’s first compare it to cellulose insulation. The choice is up to you, but here’s some information to help you decide what kind of insulation is right for your home.

Production

Before either of the two types of insulation even reaches your home, they are manufactured to produce the best possible cellulose or fiberglass insulation. In its production, cellulose ranks number one for the highest post-consumer recycled content. It is the least polluting to the environment even before it saves energy in your home.

Fiberglass also has some recycled material within its pink fibers. Fiberglass insulation averages 35% recycled content, while cellulose averages more than double that at 80%. Looking past the content, it takes more than ten times the energy to produce fiberglass than cellulose insulation.

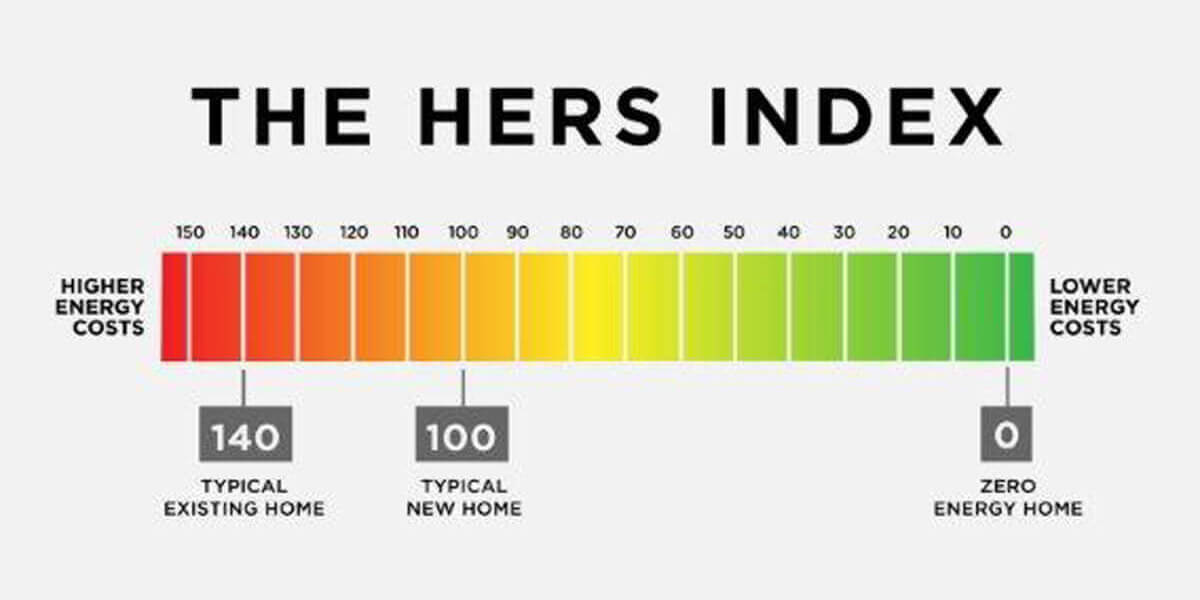

R-value

When looking for insulation, you want to find one with a high R-value, or thermal resistance. The average R-value of cellulose is 3.6-3.8 per square inch. Fiberglass’s average is slightly lower, at 3.0-3.7 per square inch. Fiberglass’s R-value ironically decreases in cold weather. So when you need you insulation the most, fiberglass actually allows more heat to escape your home. Cellulose’s R-value remains constant throughout all temperatures.

Also, cellulose helps to block airflow in the insulated areas. On the other hand, fiberglass allows air to pass freely through, making your home drafty.

Other benefits

When installed, cellulose is not only beneficial for your home’s temperature; it also helps to protect parts of your home’s frame. It is non-corrosive to steel, copper, and aluminum—materials that fiberglass will ruin. Fiberglass also acts as a bed for mildew and mold, but cellulose does not allow either to grow. Cellulose is also resistant to pests that nest in and destroy fiberglass insulation.

Fiberglass usually comes in rolled batts, which are then cut and pieced together. A batt is thick sheets of insulation that unrolls and is then ready to be cut. This technique leaves gaps between the insulation, defeating its purpose. Loose fill cellulose insulation is blown so that it fills all cracks and hard-to-reach areas. Blown installation leaves no gaps; it fills as continuous, seamless insulation.

Those are just some basic facts about cellulose and fiberglass. The choice is up to you. You can choose cellulose and choose environmentally friendly production, a better insulating performance, air sealing, building frame-friendly, and easily installed insulation, or you can choose fiberglass.